Introduction:

Portal cranes used in ship yards or railway stations are used to load and unload large amounts of heavy goods. These cranes are often continuously operating due to economic reasons, leading to an unfavorable combination of high loading and many load cycles.

Challenge:

To provide a maximum lifting weight and to keep the loads between wheels and rails within the permissible limits the steel structure of the portal crane has to be designed as a lightweight structure.

In addition, one of the most important questions regarding the cost of the crane is the required welding work that has to be done. Butt-welds especially using “backings” or “both sided welds” followed by ultrasonic inspection to ensure a high welding quality should be limited.

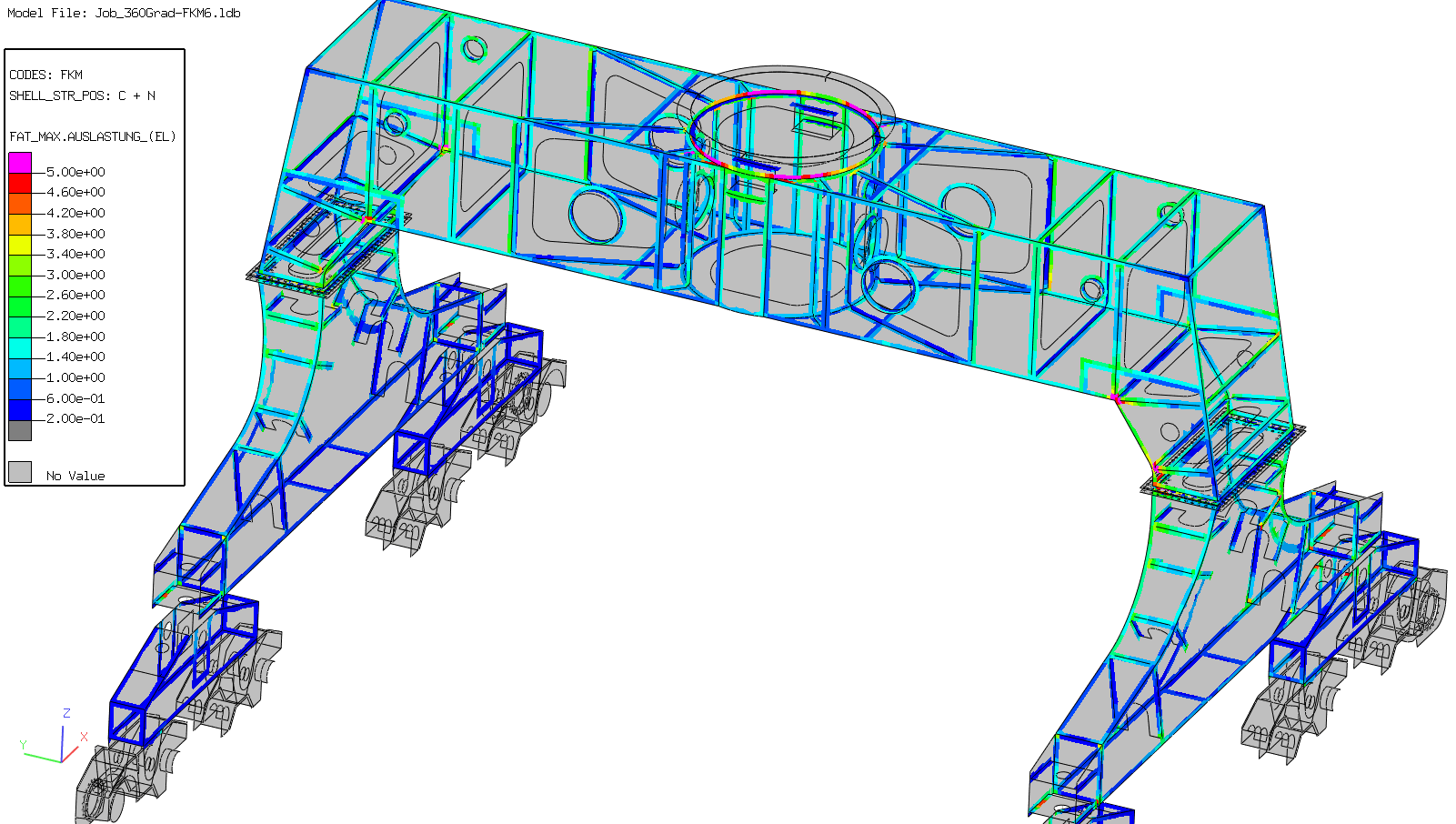

Detailed studies using LIMIT® deliver all necessary information needed to optimize the structure in terms of production cost and sufficient fatigue strength.

Advantages of using LIMIT:

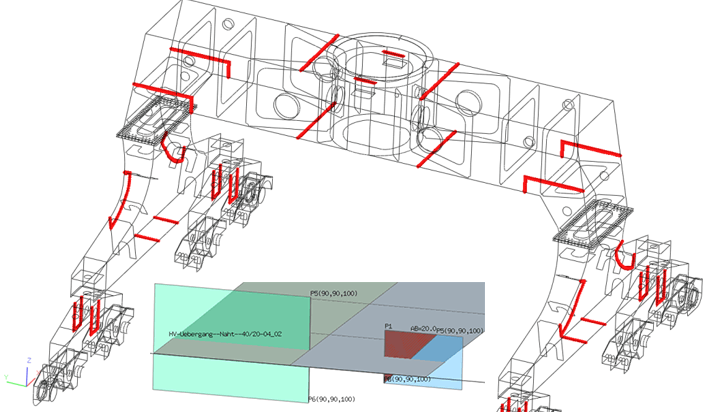

- Automated detection of the weldings by defining “Weld Sets by Feature Edges” between the given parts

- Identification of the most relevant load cases that guide the design life as direct result

- Limit the required welding of “double sided butt-welds” to only highly loaded areas

- Design the shape of the steel plates according to the required welding procedure

- Save material thickness by using ribs (also to avoid bucking)

- Use concrete filling of the bogies as counter mass

Result: Reliable and efficient design; in service for already 5 years without facing problems.