Main features of our weld calculator software

The Weld module in LIMIT® is used for the detailed assessment of seam welds. The actual weld type (butt weld, fillet weld, …) and the corresponding notch cases and FAT classes are assigned to the fatigue software according to the different guidelines. The following main features are offered:

- High flexibility since the actual weld geometry is not defined in the finite element model but in the post processing within LIMIT. This way different weld designs can be investigated without the necessity of additional FE analyses.

- Automated stress correction for nominal and structural hot spot stress concepts (see Stress Concepts Weld).

- Applicable to shell models and solid models using Sensors (see Sensor Technology).

- Different weld strength parameters depending on the loading direction with respect to the weld orientation are taken into account.

Fatigue stress parameters

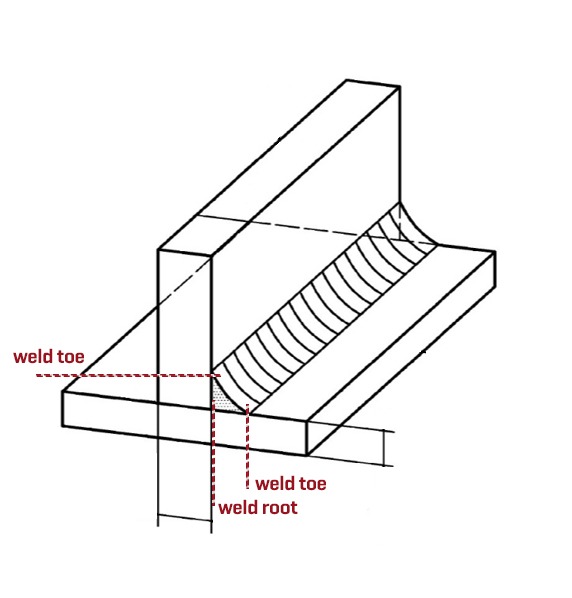

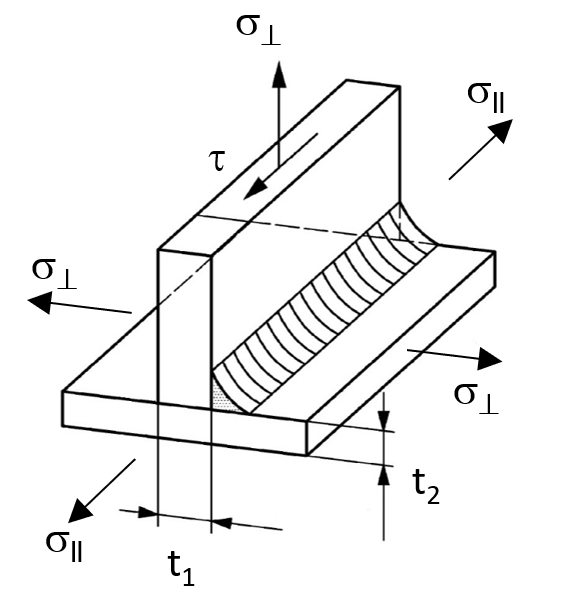

The following picture shows the stress components related to the local weld orientation. The components are the stress longitudinal to the weld σ∥, perpendicular to the weld σ⊥ and the shear stress τ. Standard assessment codes, such as FKM, EC3, DVS define different fatigue strength parameters for each of these stress components.

Advantages of LIMIT® fatigue for welded structures

- Computation of stresses in weld throats, the additional bending in one-sided welds is also taken into account (see One Sided Welds). This is possible because LIMIT® calculates the section forces and moments along the welds and uses this information to calculate the stresses for different weld types. The extraction of section forces and moments is simple in case of shell models, which makes this kind of modeling strategy very efficient for large thin-walled structures such as railway cars or other lightweight structures.

- Multiple assessment points (root, toe) are analyzed in one single run in order to cover all possible crack initiation spots of a weld (see Assessment Points in Welds). The LIMIT® fatigue analysis software allows to cover all three failure modes, which are failure of the weld toe on either of the attached sheets or the weld root.