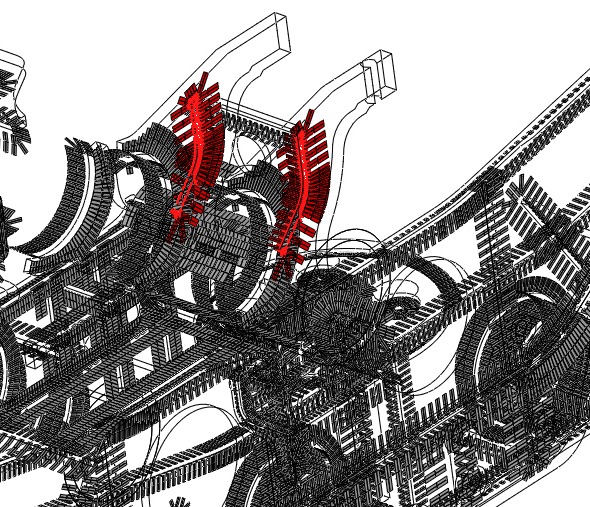

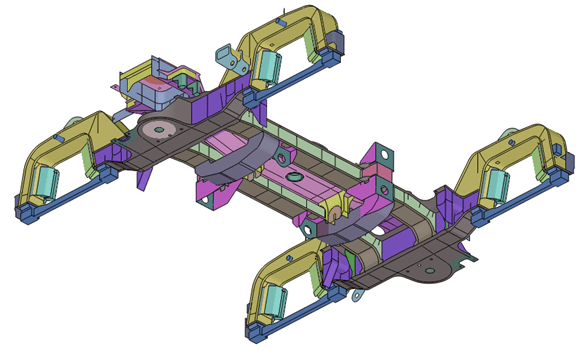

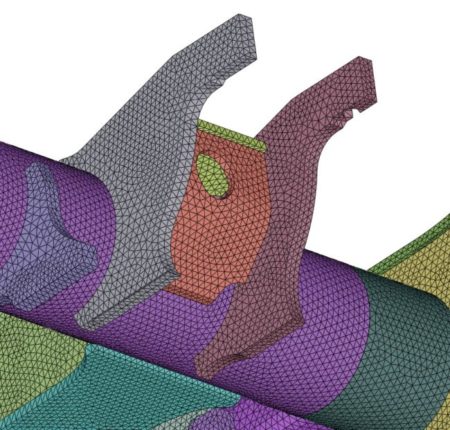

The Sensor technology is a unique feature of LIMIT®. Sensors are used for the stress assessment of welded structures based on finite element models using solid elements, not shell elements. Sensors can efficiently be used in any structure composed from metal sheets. A typical example is a bogie frame.

Using the SensorTechnology offers numerous advantages during the strength assessment. Already the finite element mesh generation can be simplified using sensors since solid models can be used instead of shell models:

- Direct volume meshing of 3D structures

- Tie/glue constraints between parts or connected meshes possible

- No mid surface shell modeling needed

- Any solid element type supported

- Weld details are not included in the solid model, but are defined in LIMIT® offering high flexibility

Important facts on Sensors:

- Sensors are generated in LIMIT® and extract section forces and moments needed for the weld throat assessment.

- Sensors deliver nominal or structural stresses and avoid stress singularities.

- Sensor Technology is less conservative than shell models and thus closer to reality.

- Sensor results can be documented by the automated report generation in LIMIT®.

- Overall the process from stress analysis to documentation of the strength assessment turns out to be very efficient.