Fatigue Analysis Software

LIMIT® is the leading software for performing fatigue strength and static strength assessments for your components according to different design codes and engineering standards.

A cutting edge fatigue analysis software has to meet three challenges: Finding the most damaging loads, checking all potential crack initiation areas such as welds and sharp notches and dealing with the complex algorithms of the fatigue codes. The fatigue analysis software LIMIT® was designed exactly for this purpose. Thus LIMIT® is the leading software for performing fatigue and static strength assessments for your components according to different design codes and engineering standards.

Benefits of Fatigue Analysis

- Identification of all critical positions in your structure with respect to static and fatigue failure

- Fast and efficient assessments of base material and weldings

- Nominal and structural (hot spot) stress available for shell and solid elements

- Graphical user-interface (GUI) for intuitive handling and to shorten training period

- Various interfaces to FEM tools (Abaqus, Ansys, Nastran, NX Nastran, Marc, OptiStruct, … )

- Individual customization of licensing to your needs

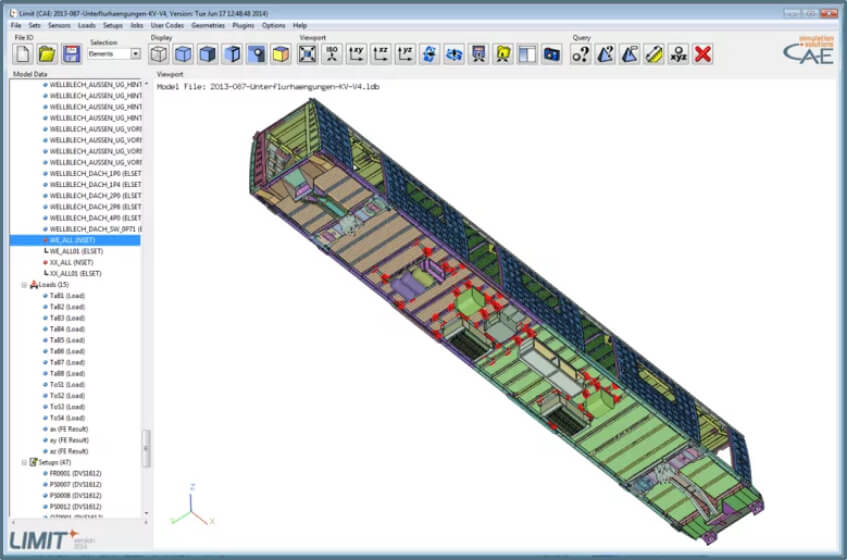

LIMIT® Software for Fatigue Analysis

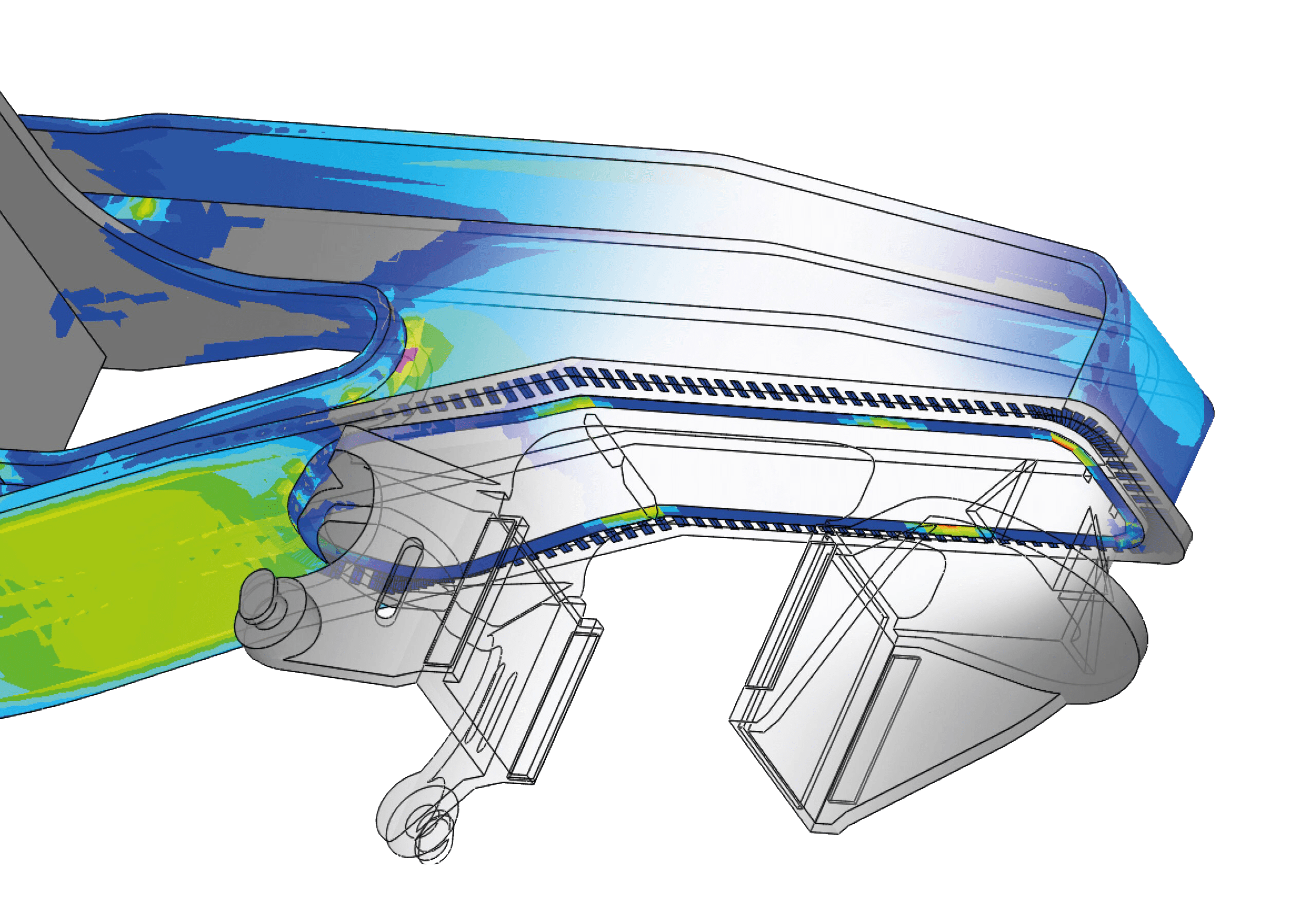

The fatigue analysis software LIMIT® operates with stress and displacement results from commercial Finite Element codes. In many cases engineers are especially interested in the fatigue of welds, since they are highly susceptible for fatigue damage. The fatigue analysis software LIMIT® supports different modelling approaches for welds including shell and solid meshes as well as nominal, structural and effective notch stress approaches.

Assessment Types

LIMIT® offers three different types of assessments: static strength, variable amplitude fatigue strength and endurance limit (constant amplitude fatigue strength).

FEA Interfaces

LIMIT® uses stress and displacement results from Finite Element analysis. Therefore interfaces to many commercial FEA packages are available such as ABAQUS, ANSYS, NASTRAN, NX-NASTRAN and many more…

Unique Features

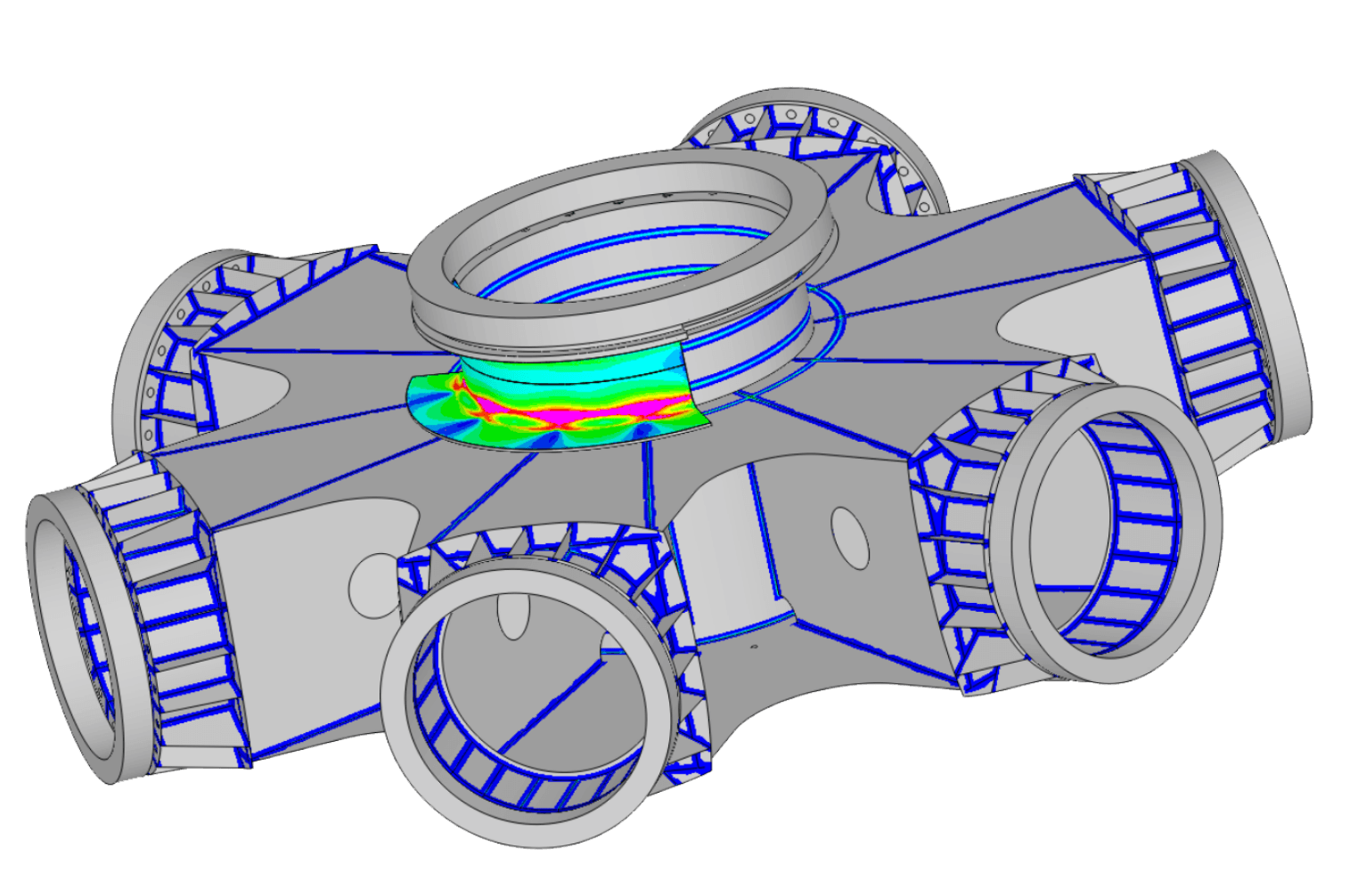

In recent years the modeling with solid elements has become more and more popular, saving time and money in the Finite Element simulation process. The fatigue analysis software LIMIT® offers a unique technology called Sensors in order to extract code conforming stresses at welds from solid model results. This special procedure supports the nominal or structural stress concept for welds and eliminates mesh dependent effects such as stress singularities. Once all welds meet the strength requirements yet another unique feature of the fatigue analysis software LIMIT® is available. LIMIT® includes an integrated report generator thoroughly documenting all parameters and results, freeing engineers from cumbersome routine work.

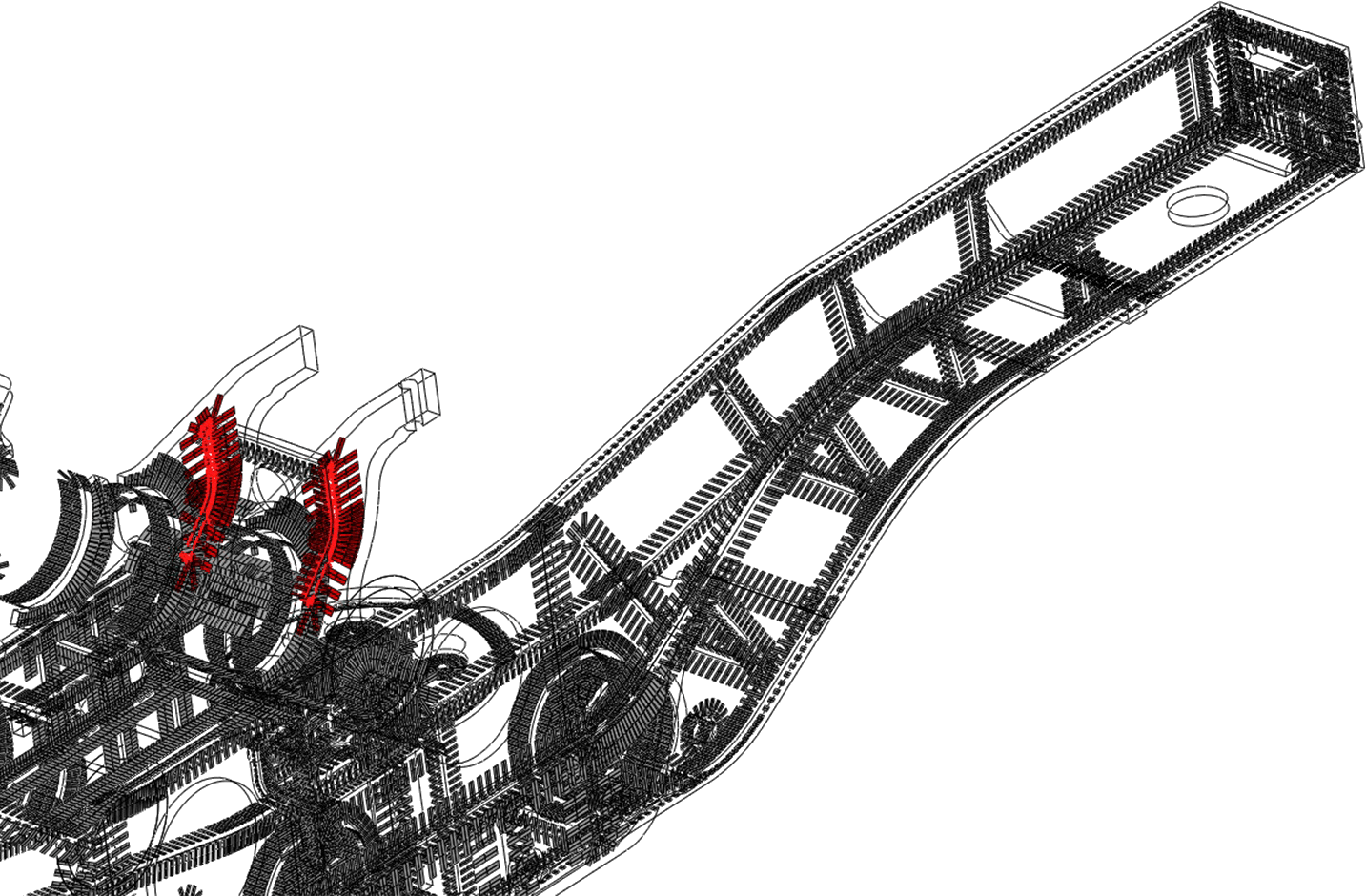

Efficient calculation of bogie frames!

The LIMIT® Sensor Technology is a unique feature and is used for the stress assessment of welded structures based on finite element models using solid elements rather than shell elements. Numerous benefits arise using this technology!

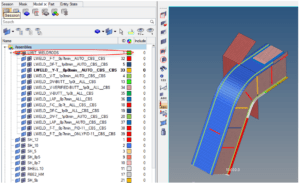

Fast definition of welds based on topology information!

After identifying all weld positions in shell models and categorizing them according to their topology, LIMIT® can automatically define the fatigue parameters using internal libraries. This process is very efficient and provides first results in a very short time!

Personalized reporting saves time and nerves!

LIMIT® includes a report generator that allows a quick and easy documentation of all data involved in a strength assessment job including the results. The report can be personalized. Furthermore the Python code of the report generator is distributed with the installation and can also be adapted by the user. As output format a .html and a latex version are available.

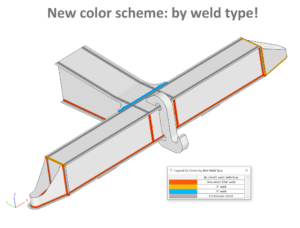

News

From Stress to Safety

The fatigue analysis software LIMIT® was developed by engineers, that use the software in their own engineering service projects. Therefore LIMIT® includes optimized workflows unmatched by other fatigue analysis software tools. LIMIT® can handle large welded structures such as railway vehicles or complete fun rides and offers a fully automated definition of the strength characteristics of welds. Complex loading situations such as MBS or measurement based data as well as non-proportional loads are covered. This way the fatigue analysis software LIMIT® can provide meaningful results in very short time. The large number of design codes and guidelines makes the fatigue analysis software LIMIT® a versatile tool for all sorts of industries and branches of engineering.

View case studies